Quality control of LED screen

Concerned about the quality of your LED display before making the final payment?

Want to understand the full quality control process behind your LED screen?

As a professional LED display manufacturer, LIGHTIN LED implements a comprehensive and rigorous quality control process.

LIGHTIN LED conducts strict quality inspections at every stage of the LED display production process.

LIGHTIN LED provides detailed pictures, videos, and a quality inspection checklist to ensure full transparency.

Pre-production preparations

Without a clear and detailed quality inspection plan from the outset, achieving a high-quality LED display becomes a significant challenge.

Quality control for LED displays must be carefully planned before production begins. This includes selecting the right raw materials, confirming product details with customers, and ensuring all specific production requirements are aligned with the factory manager.

Quality material is the foundation.

The overall performance and durability of an LED display are directly influenced by the quality of its raw materials. Ensuring the right choice of materials is crucial and must be confirmed before production begins.

Confirm the solution with the customer

Once the order is confirmed, it’s essential to review all product details with the customer multiple times—this includes the logo, structure, and any other specific requirements—to ensure everything meets expectations.

Confirm the production details.

This is the most critical step. When coordinating with the production manager, it’s vital to provide a comprehensive list of all requirements to ensure everything aligns with the customer’s order specifications.

During the LED Display Production Process

LIGHTIN LED follows strict production steps and maintains a clean, organized workshop. We provide thorough training to our employees to ensure every step of the production process meets the required standards.

Quality inspection during production is equally essential. After each production phase, our quality inspectors conduct a detailed check to ensure that no issues arise before moving to the next stage.

LED Lamp Baking

If the SMD lamp beads are not properly baked, there is a high risk of dead pixels after installation. To ensure the lamp beads function properly and maintain their longevity, baking is a standard practice before they are put into use.

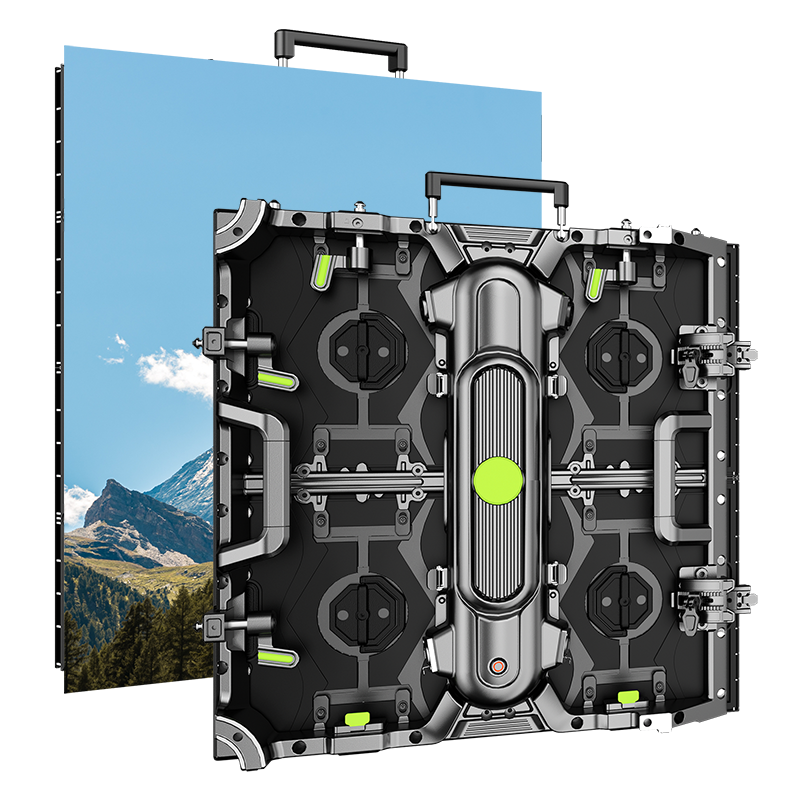

Efficient Plant & Machinery

LIGHTIN LED understands that the quality of your LED screen products is directly linked to the machinery used in production. With advanced, high-precision equipment, we ensure the most stable and exceptional LED screens, delivering superior performance and durability for your business.

Experienced Workers

LIGHTIN LED believes that only the most skilled professionals can go above and beyond to meet your demands for perfection. That’s why LIGHTIN LED continuously hires top-tier experts in the LED display industry, ensuring that every project is handled with expertise and precision.

Test for Each Light-Up

LIGHTIN LED rigorously inspects every stage of production, with a particular focus on the light-up test. This thorough process ensures that every LED display meets our high standards of performance and reliability before it reaches you.

LED Module Aging Test

The LED module aging test is a critical step before assembling the LED cabinet. LIGHTIN LED conducts a 12-hour aging test to ensure each module’s longevity and stability, guaranteeing that only the most reliable products are used in your LED displays.

Full LED Screen Aging

Once the LED cabinet is fully assembled, the entire LED display undergoes a comprehensive aging test for a minimum of 24 hours. This ensures that every component performs optimally and the final product meets the highest standards of quality and reliability.

After Completing Production

Upon completion of the LED display production, LIGHTIN LED provides the customer with three key materials: quality inspection photos, quality inspection videos, and a detailed quality inspection report.

The quality inspection photos and videos will showcase production details as requested by the customer, along with the aging effects of the red, green, blue, and white colors of the product.

In the quality inspection report, we will outline all quality checks performed, such as quantity, raw materials, size, brightness, waterproof performance tests, and more. Each inspection step will be documented in detail to ensure transparency and trust.

Before packaging, LIGHTIN LED ensures that the display is free of dead pixels, color consistency is perfect, and the product adheres to international quality standards for LED displays.

Check the Quality Inspection Videos and Pictures Below

For every order, LIGHTIN LED takes great care in conducting rigorous quality inspections to ensure our customers’ complete satisfaction. We are committed to maintaining high standards and fostering long-term partnerships through consistent product excellence and reliability.